Safety Interlocks

NK Technologies’ Current Operated Switches are available in models that will  switch at measured currents from just a few milliamps (mA) to over 100 amps. Detecting current flow is the definitive measurement to determine if equipment is on or off, a motor is running or not, a heater is on or off etc. NK’s Current Switch products are installed for interlocking for operational and safety purposes.

switch at measured currents from just a few milliamps (mA) to over 100 amps. Detecting current flow is the definitive measurement to determine if equipment is on or off, a motor is running or not, a heater is on or off etc. NK’s Current Switch products are installed for interlocking for operational and safety purposes.

Power Factor Correction Control

With ever increasing demands for electrical power the power generating  companies are beginning to penalize customers with low Power Factors. Low PFs can be considered very inefficient use of electrical energy. A low PF can be corrected by the installation of PF Correction capacitors. Although this can be achieved at the main feeder most facilities, due to multiple varying loads, choose to install PF correction on individual pieces of equipment (like a large motor) or area of plant. When a load is switched off, unless the PF correction capacitors are removed, undesirable over-correction occurs. Sophisticated automatic control systems are available but are very expensive. A simple way to switch a PF correction capacitor bank is to use an NK Technologies’ Current Operated Switch. When the load goes down, for example at night when equipment is not used, the PF correction capacitor is switched out. Then when load returns it is switched back in.

companies are beginning to penalize customers with low Power Factors. Low PFs can be considered very inefficient use of electrical energy. A low PF can be corrected by the installation of PF Correction capacitors. Although this can be achieved at the main feeder most facilities, due to multiple varying loads, choose to install PF correction on individual pieces of equipment (like a large motor) or area of plant. When a load is switched off, unless the PF correction capacitors are removed, undesirable over-correction occurs. Sophisticated automatic control systems are available but are very expensive. A simple way to switch a PF correction capacitor bank is to use an NK Technologies’ Current Operated Switch. When the load goes down, for example at night when equipment is not used, the PF correction capacitor is switched out. Then when load returns it is switched back in.

Power Transformer Monitoring

Installing an NK Technologies’ Current Transducer over the conductors on the

Most large power transformers utilize auxiliary cooling fans, drawing cooler air from a distance away from the transformer. NK Technologies’ Current Transducers or Current Operated Switches are used to monitor these fans for overload from bearing failure, under loads from drive component breakage or slippage, and to just be sure that the fan is energized and doing its required job.

Equipment Ground Fault Monitoring

As we become more aware of occupational health and safety so the need for

Generator Installations

The need for back-up power for critical loads is becoming more and more

Current Transformer Monitoring

C.T.s (Current Transformers) have been used for many years to measure AC

C.T.s step down current and the secondary has to feed into a very low impedance to maintain accuracy. In the event that the secondary is open-circuited during operation the device operates as a step-up voltage transformer since there is nowhere for the current to flow and voltages of several kV appear on the secondary, overheating occurs and combustion or explosion often results. NK Technologies’ Split-Core Current Transducers are simply and safely snapped over the shorted secondary of a C.T. to provide a fully isolated analog 4-20mA DC signal proportional to the current in the secondary, which in turn is proportional to the measured (primary) current.

NK’s Split-core Current Transducers are used to safely monitor the secondary of high voltage C.T.s used in power generation and distribution in the low voltage cubicles.

Insulation Breakdown

Industrial electrical heaters are prone to ground leakage due to the breakdown or

Heater Life Prediction

As an electric heating element ages, its resistance also changes. Many high

Vacuum Pump Monitor

Vacuum pumps are used in a variety of applications in the semiconductor industry,

Moisture Ingress on a Submersible Pump Motor

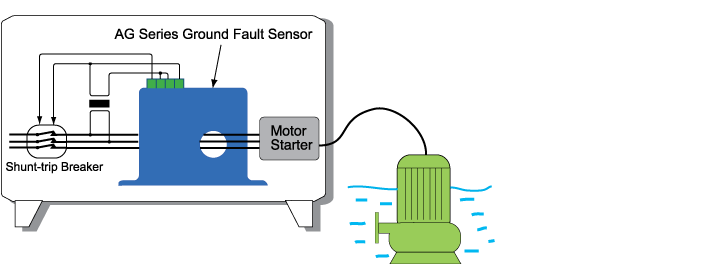

An NK Technologies’ Ground Fault Sensor installed on a submersible pump motor provides