Status Alarming

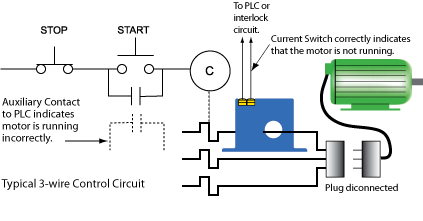

The auxiliary contacts in a motor starter are commonly used to indicate when the

At a large fish farm, failed aerator pumps resulted in massive stock losses. Because the auxiliary contacts remained closed when the pump failed, the alarm was never activated, the back-up pumps were not switched on and the fish suffocated due to lack of oxygen. Now NK Technologies’ Current Operated Switches have been installed to provide an alarm signal and a signal to automatically switch over to the back-up aerator pumps.

DC Motor Installations

Many applications requiring high torque at low speeds, like bridge cranes and log

Crusher/Grinder/Shredder Motor Interlocks

- Help prevent jamming

- Improve the uniformity of the resultant product

- Enhance overall production efficiency

By installing an NK Technologies’ Current Transducer or Power Transducer to monitor the in-feed to a crushing process, the speed of the in feed drive can be slowed when the crushing motor is working too hard, or the speed can be increased when the crusher is under worked. The analog 4-20mA proportional signal is fed directly into a VFD, and the drive does the rest of the control.

Additionally, NK Technologies’ Current Operated Switches installed on other conveying motors can be used to signal malfunction (for example over-load or motor failure) to help prevent costly equipment damage.

NK technologies current sensors come in a variety of configurations for quick and simple installation either for the OEM or End-User.