Snow Melt Systems

This application is similar to the Heat Trace System described previously, however  there is a wider choice of generally lower-cost cable, which is often attached directly to roofs and gutters, or imbedded in sidewalks, steps, driveways or car parks. Although this type of installation is sometimes exempt from the code requiring ground fault protection, it is strongly recommended. The simple installation of an NK Technologies’ Ground Fault Sensor will provide an early warning of trouble. Inevitably cable insulation deteriorates with age and stresses such as hydraulic action from ground water, resulting in current leakage to ground. This may create a hazardous situation for people or animals in contact with the installation; it will waste power and cause a significant drop in the heat output and the overall efficiency and thus effectiveness of the system. The circuit may continue to function, but snow and ice could continue to accumulate. If circuit interruption is required NK’s Ground Fault Sensor should be installed in conjunction with a contactor, shunt trip breaker or other approved circuit interruption device.

there is a wider choice of generally lower-cost cable, which is often attached directly to roofs and gutters, or imbedded in sidewalks, steps, driveways or car parks. Although this type of installation is sometimes exempt from the code requiring ground fault protection, it is strongly recommended. The simple installation of an NK Technologies’ Ground Fault Sensor will provide an early warning of trouble. Inevitably cable insulation deteriorates with age and stresses such as hydraulic action from ground water, resulting in current leakage to ground. This may create a hazardous situation for people or animals in contact with the installation; it will waste power and cause a significant drop in the heat output and the overall efficiency and thus effectiveness of the system. The circuit may continue to function, but snow and ice could continue to accumulate. If circuit interruption is required NK’s Ground Fault Sensor should be installed in conjunction with a contactor, shunt trip breaker or other approved circuit interruption device.

Ground Fault Monitoring on Heat Trace Systems

Heat trace cable is used to keep pipes or their contents from freezing, or to keep  the contents at a constant temperature while being transferred from one location to another. The most common type of heat trace cable is the self-regulating type. Self regulating cable contains two conductors and is usually physically attached to the pipe and is therefore is subject to mechanical damage. NK Technologies’ Ground Fault Sensor are frequently installed to monitor heat trace circuits and systems. When a ground fault is detected, a circuit interruption device, like a contactor or shunt-trip circuit breaker, is used to automatically disconnect the faulty circuit. In many situations NEC and/or local electrical codes require the installation of ground fault interruption devices. However ground fault sensors are commonly installed, even if not required by code, in order to monitor the condition of the heat trace cable and installation and maintain safety. Faulty circuits can be identified and then repaired or replaced at a convenient time.

the contents at a constant temperature while being transferred from one location to another. The most common type of heat trace cable is the self-regulating type. Self regulating cable contains two conductors and is usually physically attached to the pipe and is therefore is subject to mechanical damage. NK Technologies’ Ground Fault Sensor are frequently installed to monitor heat trace circuits and systems. When a ground fault is detected, a circuit interruption device, like a contactor or shunt-trip circuit breaker, is used to automatically disconnect the faulty circuit. In many situations NEC and/or local electrical codes require the installation of ground fault interruption devices. However ground fault sensors are commonly installed, even if not required by code, in order to monitor the condition of the heat trace cable and installation and maintain safety. Faulty circuits can be identified and then repaired or replaced at a convenient time.

Insulation Breakdown

Industrial electrical heaters are prone to ground leakage due to the breakdown or

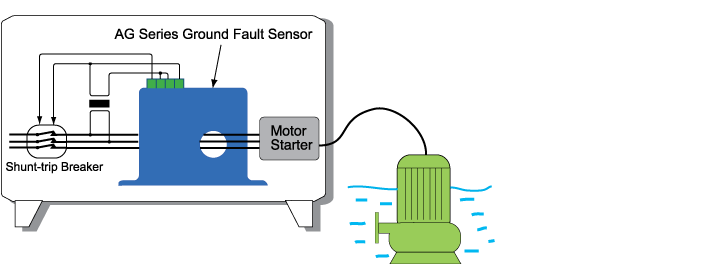

Moisture Ingress on a Submersible Pump Motor

An NK Technologies’ Ground Fault Sensor installed on a submersible pump motor provides

Pump Load Monitoring

NK Technologies’ Current Transducers are used to monitor motor current and

NK Technologies’ Power Transducers provide load monitoring in more critical applications where the addition of voltage measurement and the determination of the phase relationship between current and voltage (power factor) provides more control.

NK Technologies’ Ground Fault Sensors keep the pumps safe by measuring ground leakage currents as low as 5mA. This also provides an alternative to moisture sensors used with submersible pump motors.

Also see these other articles:

Pump Jam & Suction Loss

Moisture Ingress on a Submersible Pump Motor

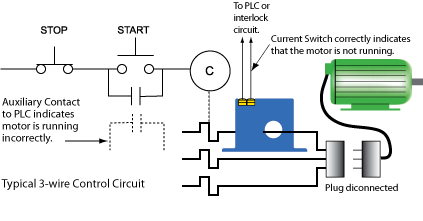

Status Alarming

The auxiliary contacts in a motor starter are commonly used to indicate when the

At a large fish farm, failed aerator pumps resulted in massive stock losses. Because the auxiliary contacts remained closed when the pump failed, the alarm was never activated, the back-up pumps were not switched on and the fish suffocated due to lack of oxygen. Now NK Technologies’ Current Operated Switches have been installed to provide an alarm signal and a signal to automatically switch over to the back-up aerator pumps.

Closed Loop Control

Normal linear AC induction motors have a current characteristic that increases with

At an engine block manufacturing facility NK Technologies’ Current Transducers provide the input to a PLC used to position the rotating wire brushes in order to clean away burrs and debris after machining. As the current, and thus the load, changes so the brushes are positioned for optimal clean-up. Similarly Power Transducers are used to control the position of wheel wash brushes in a carwash. Power measurement provides a more linear relationship for motors and other loads with non-linear current characteristics. Current Operated Switches are used to co-ordinate operations between conveyor, washing and drying systems.

DC Motor Installations

Many applications requiring high torque at low speeds, like bridge cranes and log

Conveyor Jam Protection

In situations where there may be large variations in load an NK Technologies’ Current Transducer may be used to feed motor amps to the conveyor control system, commonly a PLC. The PLC may be programmed to accommodate different setpoints for different mechanical loads so that jam protection is provided from light to heavy loads. In situations where the conveyor is not able to accept analog signals NK Technologies has developed a patented transducer with a frequency output suitable for the Digital Inputs of most PLCs.