Designed & Assembled in the USA

Home »

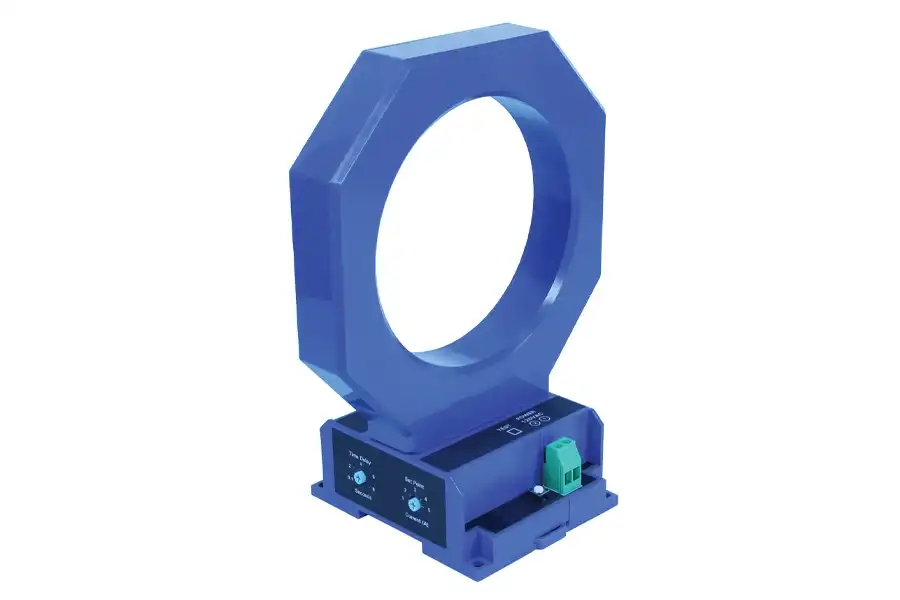

Ground Fault Relays

NK Technologies manufactures and warehouses a large selection of Ground Fault Relays to aid in your ground fault protection efforts. Begin your selection process by choosing your conductor size below. If you need a custom relay, please contact support.

Ground Fault Transducers

Ground Fault Transducers are used to measure the level of ground fault. To measure the amount of ground fault occurring, choose one of the Ground Fault Measurement Transducers below based on your conductor size requirements. If you need a custom relay, please contact support.

Here is what Engineers have to say about our technical expertise...

“Changes to NEC 210.8 B-F have challenged all of us in the industry to find new GFCI solutions. When NK Technologies reached out to us recently, we decided to invest a few hours into meeting with their application experts. Five of our electrical engineering designers attended the session and considered it time well spent. NK Technologies has an in-depth understanding of the new NEC requirements and ground fault products designed to meet them. We are thankful for their time.”

PK Electrical

One of the top electrical and low voltage/communications design firms,

in both the private and public sectors, based in Reno, NV and Denver, CO.

Ground Fault Protection By Industry

Need assistance? Please contact sales.

Ground Fault Protection Library

Below are some of our most popular ground fault protection articles and whitepapers. If you need assistance improving your ground fault protection efforts, please contact sales.

Case Studies

Frequently Asked Questions

Ground faults occur when current flows from an energized conductor to ground, which can energize other equipment and potentially cause harm if touched. Ground fault protection is critical to protect people and animals from being shocked or killed. NK Technologies, a leading supplier of current sensing and power monitoring products, offers a broad selection of ground fault relays used to prevent harm to personnel, equipment, and processes.

Ground faults can be costly if not checked. They can cause a fire to erupt, create equipment damage, or even shock or electrocute personnel. Numerous safety regulations and electrical codes exist to prevent and protect against ground faults.

Ground fault relays consist of a single magnetically permeable toroid surrounding current carrying conductors connected to an electrical device such as a motor, heater element, pump, or other machinery. The current transformer detects any imbalance through the conductors measuring current leakage to ground. The ground fault protection relay may then trigger a contactor to disconnect power or to send an alarm to a higher-level control that initiates the appropriate action.

The size of conductors, set points, and subsequent actions if a ground fault is detected all need to be considered. What do the local codes require for protection and disconnect? What is the main goal in setting up a ground fault relay? Is it focused on personnel protection or electrical device/process protection?

Ground Fault Protection Applications

Wet Environments

Irrigation pumping systems, filter pumps

Laboratory environments that use electrical equipment tied to pumping or processing fluids, or electrically powered heating processes

Chemical pumps and mixers, heat trace cables

Filling machinery, equipment in washdown/hygienic locations

Docking facilities (see Ground Fault Detection for High Current Circuits at Marina Docking Facilities)

Electrical Heating Systems

Heat treating and annealing

Heat trace systems, process heating, annealing, drying, curing, overhead cranes

Process heating (see Ground Fault Protection in Semiconductor Fabrication Equipment)

Steamers, grills, ovens, sinks and wet areas

Snow melt cable to clear sidewalks, driveways and roof gutters

General Equipment Protection

Amusement park rides, ski lifts, electrified theater chairs, stage lighting and portable power supplies

Process control equipment, pumping systems, heat trace cables

Pumping systems, cooling towers, compressor motors

Debarking, sawing, drying, cranes

Control systems, transformers, generators, solar panels, wind generators